The determining factor of device shape is the shape of the battery within. Flashlights tend to be tubular because the batteries inside are tubular. Cell phones and smart phones tend to brick shaped because the batteries inside are also brick shaped.

What if that was not a determining factor? What if our devices could be almost any shape because the battery inside could also be almost any shape?

A Spray On Lithium Ion Battery

by LiamBean

Every battery powered device we use has a particular shape. Most are barrel shaped while some or more like a bar of soap.

A Standard Battery

What defines the shape of a standard battery

Techniques and Materials

Techniques and Materials

To understand how batteries are created you, first have to imagine that all batteries consist of layers. There is a positive layer, a dialectic or insulator layer, and a negative layer. There also have to be conductive layers that allow the current flowing from negative to positive to be put to use as power. Finally the layers have to adhere to each other without interfering with each other.

Cylindrical Li Ion Battery

The battery most of us are familiar with is shaped something like a tube that is sealed at both ends. In the tube are the flat layers of components of a battery rolled into a tube shape and sealed in a protective housing. (see image right).

Flat Li Ion Battery

There's no reason for a battery to be shaped into a tube and in fact some Lithium Ion batteries are flat with the battery layers laid out as sheets of material. These battery types are often found in computers and other consumer electronics such as smart-phones, feature-phones, tablets, and netbook computers.

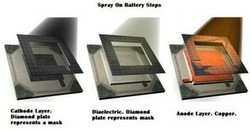

Spray On Battery Layers

Layering is applied like paint

Spray-on battery material is applied like paint. Unlike a single application type of paint, the paint-on battery is applied in layers. Each layer is composed of a different type of material (negative, dialectic, positive) and each layer must be allowed to dry (or cure) before the next layer goes on.

Battery layers are;

- electrode (cathode)

- separator (dialectric)

- electrolyte

- electrode (anode)

- current collectors

This means that each layer has to be sprayed on, allowed to dry or cure, and then the next layer applied. Of course, this also means there has to be some time between the application of the layers so that the "paint" can dry.

Each layer is a "stew," as one researcher characterized it, of compounds selected for their electrolytic and bonding properties. Each number below represents a layer.

- The current collector (positive), is a mixture of carbon nano-tubes with a mix of carbon black particles; this is suspended in N-methylpyrrolidone (a water soluble solvent).

- The cathode contains lithium cobalt oxide, carbon and ultra-fine graphite powder suspended in a binder solution.

- The polymer separator paint of Kynartm Flex resin, poly-methyl methacrylate (PMMA) and silicon dioxide; this in a solvent mixture making up the dialectric or insulator.

- The anode, is a mixture of lithium titanium oxide and ultra-fine graphite powder (UFG) suspended in a binder.

- The last layer is the negative current collector consisting of commercially available copper paint thinned with ethanol.

Spray On Battery Process Rice University |

Faster or Better?

There are tradeoffs. Are they worth it?

This is not a faster way to build a battery. In fact the cure times of the various layers contributes significantly to the amount of time it takes to create a "spray-on" battery.

However, there are some distinct advantages.

- Battery shapes are no longer limited to cylinders or bricks

- Battery shapes can conform to the device rather than the device conforming to the battery

- Engineering a device for standardized battery dimensions is no longer necessary

- Batteries can be "painted on" any suitable surface

- Batteries can be added to almost any surface

“The hardest part was achieving mechanical stability, and the separator played a critical role. We found that the nanotube and the cathode layers were sticking very well, but if the separator was not mechanically stable, they would peel off the substrate. Adding PMMA gave the right adhesion to the separator.” -- Neelam Singh

Possiblities

If the battery can be sprayed on it should also be able to be brushed on or even silk-screened. Imagine a whole new class of manufacturing which is much simpler, much more business friendly, particularly small business, and much more economical than having a custom battery designed for a device.

During the video presentation (below) one of the investigators mentions being able buy this paint-able battery at a home improvement store.

Better Battery Design

Because this paint allows the creation of a battery of any shape and size device designers will be freed of one the constraints that defines the size and shape of a device.

Batteries could be integral to a solar collection panel rather than an add-on to that panel.

Prototyping and development would be streamlined over more traditional methods.

End-users, you and I, could be free to create batteries on the fly, as needed for specific products or in emergencies.

Batteries could become truly flexible, a milestone that has, until now, not been met.

Printed Circuits and Power

Printing circuit designs with conductive paint is already a reality. This adds a new and exciting dimension to this method by providing designers and manufacturers with a way to add power to a device using the similar techniques used to create the circuits.

Functional Issues

Layer thickness and dimensions still need to be predicted in product design

There are still some issues with this method. Knowing how large the battery dimensions need to be has to be worked out prior to painting the battery on.

Also, the thickness of each layer is going to be a factor. Getting each layer the proper thickness will be an issue that involves precision as well as perfect timing. Of course, these are issues a manufacturer can readily work out, but it changes the way the design paradigm typically works.

Issues Particular to a Hobbyists Perspective

A take on "off the shelf" battery kits

Hobbyists will jump at this and cost consideration will be secondary. But there are some issues the kit maker will need to address for successful marketing.

Consistency

The "paint-on" battery will likely come in a package with numbered (5 by the author's count) cans or containers. The "paint" will have to have a common (or close to common) viscosity for each layer. This way the consumer will be able to do an effective job of creating a battery without a high degree of professional skill required. The viscosity is directly related to how thickly the layers can or should be applied. A very important consideration for consistent results.

Drying (Curing) Times

Unless the kit maker can bring some standardization to the kit, the consumer will have to follow the directions to the letter. Not allowing one layer to cure sufficiently before the next is applied could become a real issue. Consider that one of the major problems with traditional Li-Ion batteries is short circuits between layers.

These short-circuits have led to severe overheating and the occasional fire, therefore the consumer will have to be adequately warned to rigorously adhere to the instructions.

Charging Times and Storage Capacity

There is no word on how long it takes to charge one of these batteries. Storage, for now at least, seems to be limited. In the video below the eight bath tiles painted with the battery powered the "Rice" display for seven hours. Since the display is LED, a very lower power consumption light device, this is not terribly good.

But, and this is a big "but," this is very good for a storage medium that is literally brand new.

Toxicity Issues

Another possible roadblock to the hobbyist is the toxicity of some of the solvents and the lithium layers themselves. The kit manufacturer will have to address these issues and likely approach the EPA and the FDC for commercial approval.

Rice University and the Research Team

Rice University has long been known as the Harvard of the South, but with this latest very remarkable development, that may change. Rice could very well become known as the "MIT" of the South.

In a remarkable breakthrough researchers Neelam Singh (lead) Charudatta Galande and Akshay Mathkar, along with alumn Wei Gao, and research scientist Arava Leela Mohana Reddyand have developed a lithium ion battery that can be sprayed onto surfaces,just like paint.

This may seem odd or even silly at first. But when you consider the battery within an object strongly affects its size and shape this development could bring a radical change to the shape our battery powered objects take.

Recycling Issues

Recycling this type of battery will be very difficult at best. However, since this battery has to be "painted" on a non-porous surface it may be possible to work this out somehow.

Coda

Coda

This may not seem like such an important development at first glance, but flexible batteries that can conform to the internal or external dimensions of the object they power is a huge breakthrough.

I've tried to present some potential uses here, but I'm certain I haven't even scratched the surface of possibilities for this technology.

You might also like

The HalogensA description of the chemistry of the elements in Group 7 of the Periodic Table

The Engineering Mastery of the Wright BrothersMost people recognize that the Wright brothers mastered powered flight, but f...

Crêpes and Crêpe Disheson 09/14/2016

Crêpes and Crêpe Disheson 09/14/2016

About Me - Liam Beanon 11/28/2014

About Me - Liam Beanon 11/28/2014

About Ebolaon 11/08/2014

About Ebolaon 11/08/2014

Comments

Rose: I'm sorry that I didn't see this earlier. For the most part I think you are correct. There is an exception though. That would be a device that has a non-standard shape.

They'll only switch to spray on batteries if they cost less to make than conventional batteries. Not sure when that will happen though...