Whether patching drywall or working with wood, no project is complete without making sure your surface is smooth. Whether you are using a power sander or going the old-fashioned manual sanding route, choosing the correct sandpaper grit and type will provide your finished product with a beautiful look and feel. There are many sandpaper options on the market so let’s take a look at how to choose the right one for your project

Choosing The Right Sandpaper

by AceHardware

How to choose the right sandpaper for your woodworking project.

Types of Sandpaper

Currently there are two types of sandpaper available: commercial and industrial. Commercial sandpapers are readily available and are used in most home DIY projects requiring sanding. Industrial grade sandpapers are mostly found in supply stores and made from higher grade materials to withstand heavy use. The differences between the two lie in the materials used for the grit, the backing paper and the glue holding the grit and paper together.

The Right Grit

Grit refers to the amount of abrasive material per square inch of the sandpaper. A coarse piece of sandpaper will have a lower grit number, while a fine piece will have a higher number. It is recommended to sand with course grit first and progressively move to a finer grit that will ultimately leave a smooth finish.

Here are the six grades of sandpaper and their uses:

- Course (40-60) : Heavy sanding and stripping; first defense against badly scratched surfaces

- Medium (80-120): Smoothing and leveling; removes smaller scratches and marks

- Fine (150-180): Final sanding before staining or treating wood

- Very Fine (220-240): Sanding between coats of stain or wood treatment

- Extra Fine (280-320): Removal of marks or blemishes between finish coats

- Super Fine (360 and above): Used for high finish; dulls luster for additional finish coats

Types of Abrasives

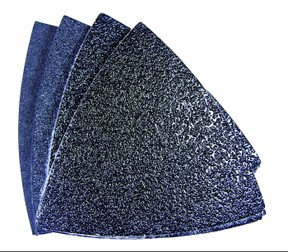

Sandpaper comes in four popular types: Aluminum Oxide, Garnet, Silicon Carbide and Ceramic. While mostly used for wood, some sandpaper can be used for metal or other materials. Aluminum Oxide and Garnet are the two most widely used types of abrasives.

Sandpaper comes in four popular types: Aluminum Oxide, Garnet, Silicon Carbide and Ceramic. While mostly used for wood, some sandpaper can be used for metal or other materials. Aluminum Oxide and Garnet are the two most widely used types of abrasives.

- Aluminum Oxide: Most commonly used for power sanders, aluminum oxide is the most popular choice for woodworkers. This paper is extremely durable and lasts longer than other sandpapers.

- Garnet: Common wood sandpaper, garnet leaves a beautiful finish and is used mostly for finish sanding.

-

Silicon Carbide: Usually not used in woodworking, silicon carbide works great on metal, fiberglass paint and plastic due to its hard abrasive makeup.

- Ceramic: Made of durable abrasives and able to handle a large amount of material at once, ceramic sandpaper is commonly used in belt sander belts.

Sanding Tips

When sanding a piece of furniture or other wood project, keeping these sanding rules in mind will help you achieve the finish you’re going for:

- Sand with the grain, never against. This ensures a smooth finish and no sander snags.

- If your job requires “fine-sanding” don’t use a coarse paper. This could potentially destroy your finish.

- Start with the coarsest grit paper and work down to the finest. This will ensure a luxurious finish.

- Let the sandpaper do the work. Don’t force it!

Selecting the right sandpaper for the task at hand is essential for a beautiful finish. For more information on power sanders and other tools check out this handy power tools buyer’s guide!

You might also like

Use Essential Oils to keep spiders awayUsing essential oils is a great natural and inexpensive method to keep spider...

How to build the perfect garage workbenchLighted workbench in the garage makes the perfect spot for craft projects, bu...

A Guide to Outdoor Grill Coverson 09/27/2012

A Guide to Outdoor Grill Coverson 09/27/2012

Comments