With a growing need for increased precision welding, the birth of the plasma welding technique was developed.

The introductory version was presented in 1964 and has continued to meet the changing needs of the precision welder.

Today this technique provides high quality welds to miniature projects or precise welds to those that demand this type of work.

The plasma welder functions at an equal level in both a manual weld as well as automatic applications.

The range of use is great. It has been utilized in aircraft repair, welding of surgical equipment, high volume strip metal welding as well as some common household appliances among other applications.

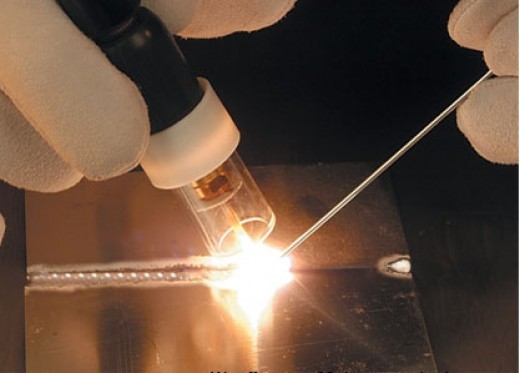

The actual process of plasma welding heats a gas (plasma) to such extreme temperatures that it causes the gas to become ionized. Once ionized, the gas is then electrically conductive.

It is through this gas (plasma) that an arc is transferred to the piece waiting to be welded.

The extreme heat that is transferred to the metal through the arc, melts the intended work piece and fuses it together.

In addition, this plasma is forced through a restricted opening of the gun offering the operator an extremely concentrated arc of heat.

This type of performance concludes in a high quality finish.

Pro-Fusion offers a Dual-Arc 80 Micro-TIG/Plasma System that allows flexibility for the operator with the capabilities of both TIG and Plasma welding.

The plasma advantages include extended electrode use prior to contamination, gentle arc transfer as well as higher weld speeds in some applications.

Making Money Online is Not Impossible, It Just Takes Putting Yourself Out Thereon 09/25/2012

Making Money Online is Not Impossible, It Just Takes Putting Yourself Out Thereon 09/25/2012

Thump. Looking For True Loveon 09/28/2012

Thump. Looking For True Loveon 09/28/2012

Cure Tooth Decay Ramiel Nagel And Dr. Weston Price's Nutrition and Physical Regeneration Bookson 03/17/2013

Cure Tooth Decay Ramiel Nagel And Dr. Weston Price's Nutrition and Physical Regeneration Bookson 03/17/2013

Cleaning Wool Rugs - Excellent Results At Homeon 03/10/2013

Cleaning Wool Rugs - Excellent Results At Homeon 03/10/2013

Comments