Another commonly used form of welding is the Gas Metal Arc Welding (GMAW) also known as MIG (Metal Inert Gas) welding. In contrast to SMAW, MIG welding is a semi-automatic to a fully automatic form of welding.

During this process, a consumable wire electrode with a shielding gas is continuously fed through the welding gun. It was initially used to weld aluminum but due to the decreased welding time, it offered it has been further developed to successfully weld steel. The general technique is simple where the operator guides the welding gun along as they are being welded. MIG welding is most often seen in the automotive industry.

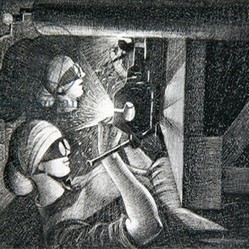

Again, when one is ready to compare welders the leading companies are a good place to start. Hobart offers the Handler 187 (pictured above, click image to view on Amazon) with small running gear and cylinder rack. It's able to weld a variety of metals including aluminum, stainless steel and other mild steels. In addition, for those jobs that are in areas of volatile air movement, this version offers the flux cored self-shielding option.

Starting at just over $700.00, this welder creates an arc that matches metal thickness and requires little clean up.

Making Money Online is Not Impossible, It Just Takes Putting Yourself Out Thereon 09/25/2012

Making Money Online is Not Impossible, It Just Takes Putting Yourself Out Thereon 09/25/2012

Thump. Looking For True Loveon 09/28/2012

Thump. Looking For True Loveon 09/28/2012

Cure Tooth Decay Ramiel Nagel And Dr. Weston Price's Nutrition and Physical Regeneration Bookson 03/17/2013

Cure Tooth Decay Ramiel Nagel And Dr. Weston Price's Nutrition and Physical Regeneration Bookson 03/17/2013

Cleaning Wool Rugs - Excellent Results At Homeon 03/10/2013

Cleaning Wool Rugs - Excellent Results At Homeon 03/10/2013

Comments

Jerrico, I once thought of taking a welding class at a community college.